Printed circuit board (PCB) fabrication involves complex manufacturing processes prone to unpredictable delays even under normal conditions. However, current supply chain disruptions, labor shortages and rising material costs further threaten lead time reliability putting product schedules at risk.

This guide examines key sources of PCB fabrication delays and recommends practical mitigation strategies to contain variability. Following structured risk management principles during design, component sourcing and order placement reduces delays for more predictable on-time deliveries.

Understanding Manufacturing Lead Times

Before examining delay risks, first review basics of standard PCB production lead times from order placement to delivery when processes run smoothly.

Typical Manufacturing Durations

Under ideal conditions, expect approximate fabrication durations:

- Standard Technology - 15-20 days minimum

- Advanced HDI - 20-30 days minimum

- Rigid-Flex - 25-45 days minimum

Where Delays Originate

Common stages adding variability:

- Material shortages

- Equipment downtimes

- Engineering change orders

- Customs inspections

- Transit logistics

While absolute lead times continue to extend in 2023, focusing risk mitigation on these key phases containing the most uncertainty pays the greatest dividends.

Top Production Delay Risk Factors

Specific scenarios frequently delay PCB deliveries through upstream root causes outside of fabrication facility control.

Component Sourcing Issues

Tight supplies on critical ICs, passives, connectors or any parts needed for assembly lengthen production if kits unavailable when boards complete. Factors include:

- Global chip shortages

- Regional supply chain events

- Extended vendor lead times

- Minimum order quantities

- Allocation restrictions

- Counterfeit parts entering supply chains

Guarding against shortages requires advanced strategic planning when selecting board-mounted components.

PCB Design Complications

Last minute engineering change orders (ECOs) or releasing designs still undergoing review and adjustments leads to revisions or cancelled builds extending timelines:

- Insufficient design rule checking

- Incomplete library parts

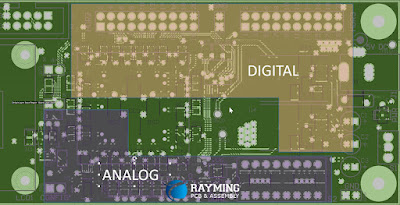

- High layer counts and densities

- Adding requirements late

Locking down deliverables earlier prevents delays from modifications.

Long Shipping Transits

Transport capacity bottlenecks especially on intercontinental freight routes stretch delivery dates once boards actually ship:

- Container/cargo availability

- Port processing backups

- Airline routing changes

- Local trucking/postal delays

While hard to accelerate physical transit times, understanding current logistics trends helps set expectations.

Payment and Contract Fulfillment

Administrative oversights interrupt order commencement or progression until resolved:

- Upfront deposit shortages

- Delayed milestone payments

- Incomplete paperwork like ITAR/EAR forms

- Unsigned NDA agreements

Staying on top of all business prerequisites keeps focus strictly on production.

Risk Mitigation Strategies and Methods

Taking action to address potential delays proactively throughout all stages reduces schedule uncertainty despite wider industry volatility.

Requirements Finalization

Start mitigating risks by ensuring rigid product requirements and stable deliverables upfront before engaging contract manufacturing resources:

- Freeze schematics/layouts after sufficient prototype testing

- Complete component selection well ahead of orders

- Resolve all specification open questions

- Obtain internal stakeholder approvals

This reduces downstream change orders and the resulting delays.

Regular Project Reviews

Continually reviewing status through the contract manufacturer’s (CM) production stages allows catching bottlenecks early for quicker resolution:

- Weekly project scheduling calls

- Visibility to CM inventory/capacity

- Tracking open action items/approvals

- Monitoring for execution changes

Reviews provide the shortest reaction times to dynamic issues.

Contingency Planning

Hope for the best while preparing contingency options if delays materialize:

- Build slack into project schedules

- Explore alternate component substitutions

- Qualify secondary CMs in parallel

- Prepare risk impact explanations for stakeholders

Documented workarounds demonstrate proactive crisis management if needed.

Configuration Control

Refers to strict change management discipline once deliverables baseline by controlling modifications:

- Change review boards approve adjustments

- Updated requirements undergo revalidation

- Alterations require specified lead time increases

Freezing the design protects efficiency.

Applying practical risk avoidance alongside flexibility at every interaction opportunity compresses both schedule durations and variability regardless of external volatility.

Delay Risk Assessment Case Study

Consider recent real-world scenarios highlighting the value of vigilant risk mitigation on complex PCBA deliveries:

Project Background

A medical diagnostic equipment startup sought custom instrument controller boards from contract manufacturer FlashFab incorporating both:

- Advanced 8 layer FR4 SMT controller

- 6 layer flex/rigid sensor interface

Changing Requirements

The startup continued iterating component selection and interface needs even after design handoff while seeking FDA compliance:

- Additional sensor inputs increased layer counts

- Sensor analog drive rework caused cabling changes

- Review delays pushed baselining back 4 weeks

Supply Issues

Long lead times on several precision op-amps and optical components outdated preliminary sourcing:

- 20 week leads on op-amp alternatives

- Minimum order quantities increased on receiver chips

- Cost spikes hit various passive components

Mitigation Success

Extensive collaboration between the startup and FlashFab prevented fatal delays through mitigation:

- Schematics partitioned reducing changes

- Prequalified secondary op-amps

- PCBA build adjusted to changing stocks

- Partial builds shipped while confirming sensors

The project ultimately delivered only 2 weeks behind original targets despite substantial volatility thanks to coordinated risk assessment.

Implementing Risk Management Processes

Presented strategies outline general risk principles - real results require concrete systematic solutions capturing interdisciplinary perspectives across product teams.

Risk Management Roles

Establish clear owners and participants for risk processes:

- Program managers: Overall moderators

- Engineers: Technical domain authorities

- Purchasers: Supply chain insights

- Quality leads: Standards impacts

- Executive sponsors: Final approvers

Covering all viewpoints ensures comprehensive identification.

Structured Risk Logging

Log every substantial foreseeable delay intracking systems detailing:

- Source risk description

- Likelihood and root causes

- Estimated schedule impact

- Mitigation approach and ownership

This codifies mitigation monitoring with audit trails.

Quantitative Cost/Benefit Analysis

Weigh proposed tactics against alternatives mathematically:

- Evaluate mitigation costs in time/resources

- Model quantified schedule recovery

- Prioritize by risk-adjusted returns

Numbers justify optimal choices.

Design Reviews Focused on Risks

Expand required reviews like PDRs and CDRs to highlight project uncertainties:

- Create risk-focused agendas

- Debate scenarios and gather data

- Develop consensus decisions on actions

Reviews provide collaborative direction.

Formalizing procedures around risk management introduces needed rigor benefiting complex electronics projects.

Conclusion

With expanding lead times now the norm, waiting around for PCB fabrication involves ever more unpredictability that jeopardizes product releases dependent on custom boards unavailable elsewhere.

By targeting known delay factors using a mix of proactive design choices, supply chain adjustments, close manufacturer coordinations and disciplined change control, programs regain influence over outcomes despite industry turmoil.

Implementing the risk assessment and mitigation best practices outlined here reduces existing lead time variability. Building effective custom electronics requires accepting new realities while navigating around roadblocks aggressively through shared accountability between technical and business teams across organizations.

Frequently Asked Questions

What is the easiest way to start applying risk management?

Focus first on consistent requirements documentation and change control processes. avoids introducing unnecessary turbulence.

How much lead time savings can be realistically expected after risk mitigation?

For an average project, between 20-30% reduction of lead time variability allowing better predictability.

What is the most accurate way to estimate lead times?

Collect ongoing benchmark data from your contract manufacturing partner tracking current localized conditions factored together with historical quoting from completed runs.

Should every minor risk be mitigated equally?

No, allocate mitigation effort proportional to likelihood an issue emerges multiplied by the corresponding estimated impact. Avoid over-optimizing fringe scenarios.

Is it advisable to place orders with backup manufacturing sources in parallel?

Yes, dual sourcing identical boards provides insurance against delays although at higher expenses if both deliver successfully. Determine based on project budgets and risk tolerance.

No comments:

Post a Comment