Introduction to Flexible Aluminum PCBs

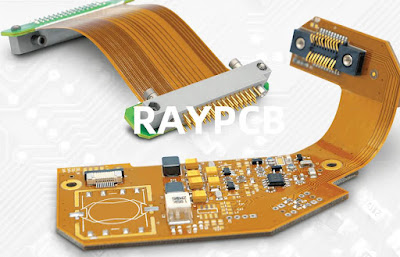

Flexible aluminum printed circuit boards (PCBs) represent a revolutionary advancement in electronic design and manufacturing, combining the superior thermal management properties of aluminum substrates with the mechanical flexibility required for modern electronic applications. These innovative circuit boards have emerged as a critical solution for industries demanding both high-performance thermal dissipation and conformable designs.

The evolution of flexible aluminum PCBs stems from the growing need to address thermal challenges in increasingly compact and powerful electronic devices. Traditional rigid PCBs often fall short in applications requiring heat dissipation while maintaining flexibility, creating a significant gap in the market that flexible aluminum PCBs successfully fill.

Unlike conventional flexible PCBs that primarily use polyimide substrates, flexible aluminum PCBs incorporate aluminum as the base material while maintaining bendability through specialized construction techniques. This unique combination offers unprecedented thermal performance in applications where space constraints and heat generation pose significant design challenges.

Understanding the Structure and Composition

Core Materials and Layers

Flexible aluminum PCBs feature a sophisticated multi-layer construction designed to optimize both thermal performance and mechanical flexibility. The typical structure consists of several critical layers, each serving specific functions in the overall performance profile.

The aluminum substrate forms the foundation of these PCBs, typically utilizing high-purity aluminum alloys with excellent thermal conductivity properties. The aluminum core thickness varies depending on application requirements, generally ranging from 0.5mm to 3.0mm, with thinner substrates providing greater flexibility while thicker ones offer superior thermal dissipation.

Above the aluminum substrate lies the dielectric layer, which serves as electrical insulation while facilitating thermal transfer. This layer represents one of the most critical components in flexible aluminum PCB design, as it must maintain electrical isolation while allowing efficient heat transfer from the copper traces to the aluminum substrate.

The copper layer, where electronic circuits are formed, sits atop the dielectric material. Copper thickness in flexible aluminum PCBs typically ranges from 1 oz to 4 oz, depending on current carrying requirements and thermal considerations. The copper circuitry design must account for the flexibility requirements while maintaining electrical performance.

Dielectric Materials and Properties

The selection of dielectric materials significantly impacts the performance characteristics of flexible aluminum PCBs. Common dielectric materials include thermally conductive adhesives, ceramic-filled polymers, and specialized flexible thermal interfaces.

Thermally conductive adhesives represent the most common choice for flexible aluminum PCBs, offering thermal conductivities ranging from 1.0 to 5.0 W/mK while maintaining the flexibility required for bendable applications. These materials typically consist of silicone or acrylic bases filled with thermally conductive particles such as aluminum oxide, boron nitride, or aluminum nitride.

Advanced ceramic-filled polymers provide enhanced thermal performance, achieving thermal conductivities up to 8.0 W/mK while maintaining reasonable flexibility. However, these materials often require careful consideration of mechanical stress factors to prevent delamination during flexing operations.

Manufacturing Processes and Techniques

Specialized Production Methods

The manufacturing of flexible aluminum PCBs requires specialized processes that differ significantly from traditional PCB production. The process begins with aluminum substrate preparation, involving surface treatment and cleaning procedures to ensure optimal adhesion of subsequent layers.

Surface treatment typically includes chemical etching or mechanical roughening to increase surface area and improve adhesion characteristics. The aluminum surface may undergo anodization processes to create a controlled oxide layer that enhances dielectric properties while maintaining thermal conductivity.

The dielectric layer application represents a critical manufacturing step, requiring precise control of thickness and uniformity. Screen printing, roller coating, or lamination techniques may be employed, depending on the specific dielectric material and thickness requirements.

Copper layer application follows dielectric curing, utilizing either adhesive bonding of copper foil or direct copper plating processes. The choice between these methods depends on copper thickness requirements, adhesion specifications, and cost considerations.

Quality Control and Testing Procedures

Manufacturing flexible aluminum PCBs demands rigorous quality control procedures to ensure both electrical performance and mechanical reliability. Testing protocols must address thermal performance, electrical characteristics, and mechanical flexibility parameters.

Thermal testing includes thermal conductivity measurements, thermal cycling tests, and thermal shock evaluations. These tests verify the PCB's ability to dissipate heat effectively while maintaining structural integrity under varying temperature conditions.

Electrical testing encompasses standard PCB electrical tests such as continuity, insulation resistance, and impedance measurements, with additional considerations for the effects of flexing on electrical performance.

Mechanical testing evaluates flex life, bend radius limitations, and adhesion strength between layers. These tests ensure the PCB can withstand expected mechanical stresses during installation and operation.

Applications and Industry Use Cases

LED Lighting Applications

Flexible aluminum PCBs have found extensive application in LED lighting systems, where effective thermal management is crucial for maintaining LED performance and longevity. The combination of excellent heat dissipation and mechanical flexibility makes these PCBs ideal for curved LED strips, architectural lighting, and automotive lighting applications.

In automotive lighting, flexible aluminum PCBs enable the creation of curved headlight assemblies and tail lights that follow vehicle contours while providing superior thermal management. The aluminum substrate efficiently conducts heat away from high-power LEDs, preventing thermal degradation and extending operational life.

Architectural lighting applications benefit from the ability to create curved and flexible lighting solutions that can conform to building contours and decorative elements. The thermal management properties ensure consistent light output and color temperature across extended operating periods.

Automotive Electronics

The automotive industry has embraced flexible aluminum PCBs for various applications requiring both thermal management and space efficiency. Engine control modules, power electronics, and infotainment systems increasingly utilize these PCBs to address thermal challenges in confined spaces.

Under-hood automotive applications particularly benefit from the thermal properties of aluminum substrates, as these environments subject electronic components to extreme temperature variations. The superior heat dissipation capabilities help maintain electronic component reliability in challenging thermal conditions.

Power electronics applications in electric and hybrid vehicles utilize flexible aluminum PCBs for motor controllers, battery management systems, and charging electronics. The combination of thermal management and mechanical flexibility enables compact designs while ensuring reliable operation under high power conditions.

Consumer Electronics and Mobile Devices

Consumer electronics manufacturers increasingly adopt flexible aluminum PCBs to address thermal challenges in compact device designs. Smartphones, tablets, and wearable devices benefit from the space-efficient thermal management solutions these PCBs provide.

Wearable electronics represent a particularly compelling application, as these devices must conform to body contours while managing heat generation from processors and wireless communication components. Flexible aluminum PCBs enable thin, conformable designs while preventing uncomfortable heat buildup.

Gaming devices and high-performance mobile electronics utilize flexible aluminum PCBs to manage heat from powerful processors and graphics components while maintaining slim profile designs. The thermal management capabilities help maintain performance levels during intensive operations.

Technical Specifications and Performance Parameters

Thermal Performance Characteristics

The thermal performance of flexible aluminum PCBs significantly exceeds that of traditional flexible PCBs, with thermal conductivity values typically ranging from 1.5 to 8.0 W/mK depending on construction and materials. This represents a substantial improvement over standard polyimide flexible PCBs, which typically exhibit thermal conductivity values of 0.2 to 0.4 W/mK.

| Parameter | Flexible Aluminum PCB | Standard Flexible PCB | Improvement Factor |

|---|---|---|---|

| Thermal Conductivity | 1.5-8.0 W/mK | 0.2-0.4 W/mK | 4x-20x |

| Operating Temperature | -40°C to +150°C | -40°C to +125°C | Extended range |

| Thermal Resistance | 0.5-2.0 °C/W | 5.0-15.0 °C/W | 3x-10x better |

| Heat Dissipation | Excellent | Poor to Fair | Significant |

Electrical Performance Properties

Despite the focus on thermal management, flexible aluminum PCBs maintain excellent electrical performance characteristics. The dielectric properties ensure proper electrical isolation while the copper circuitry provides low-resistance current paths.

Typical electrical specifications include dielectric strength values ranging from 2000V to 5000V, depending on dielectric thickness and material selection. This ensures adequate electrical isolation between the copper circuitry and aluminum substrate.

| Electrical Parameter | Typical Value | Test Conditions |

|---|---|---|

| Dielectric Strength | 2000-5000V | Per IPC standards |

| Insulation Resistance | >10^12 Ohms | At 500V DC |

| Dielectric Constant | 3.0-4.5 | At 1 MHz |

| Dissipation Factor | 0.01-0.03 | At 1 MHz |

| Copper Conductivity | >95% IACS | Standard test |

Mechanical Properties and Flexibility

The mechanical properties of flexible aluminum PCBs represent a careful balance between flexibility and structural integrity. The aluminum substrate provides mechanical strength while specialized construction techniques enable the required flexibility.

Minimum bend radius specifications typically range from 5mm to 25mm, depending on substrate thickness and construction details. Thinner substrates naturally provide smaller bend radii but may sacrifice some thermal performance.

Flex life specifications vary considerably based on application requirements and construction parameters. Static flexing applications may require minimal flex life, while dynamic applications may demand hundreds of thousands of flex cycles.

| Mechanical Parameter | Range | Factors Affecting Performance |

|---|---|---|

| Minimum Bend Radius | 5-25mm | Substrate thickness, construction |

| Flex Life (Static) | >1000 cycles | Application dependent |

| Flex Life (Dynamic) | 10,000-100,000+ | Design optimization required |

| Tensile Strength | 150-300 MPa | Material selection |

| Operating Temperature | -40°C to +150°C | Material dependent |

Design Considerations and Best Practices

Circuit Layout Optimization

Designing circuits for flexible aluminum PCBs requires careful consideration of thermal, electrical, and mechanical factors. Circuit layout optimization focuses on maximizing thermal transfer to the aluminum substrate while maintaining electrical performance and mechanical reliability.

Component placement strategies should prioritize heat-generating components in areas with optimal thermal paths to the aluminum substrate. Power components, processors, and high-current circuits benefit from direct thermal coupling to the aluminum layer through optimized dielectric materials.

Copper trace design must account for thermal expansion differences between copper and aluminum while maintaining electrical performance. Trace routing should avoid sharp corners and abrupt direction changes in flex zones to prevent stress concentration and potential failure.

Thermal Management Strategies

Effective thermal management in flexible aluminum PCB design requires understanding heat flow paths and optimizing thermal interfaces. The primary thermal path involves heat transfer from copper traces through the dielectric layer to the aluminum substrate.

Thermal via design plays a crucial role in enhancing heat transfer from components to the aluminum substrate. Strategic placement of thermal vias can significantly improve thermal performance, particularly for high-power components.

Heat spreader integration within the aluminum substrate can further enhance thermal performance by distributing heat over larger areas. This approach proves particularly effective for applications with concentrated heat sources.

Mechanical Design Guidelines

Mechanical design considerations for flexible aluminum PCBs focus on stress distribution, bend radius optimization, and fatigue resistance. Understanding stress patterns during flexing operations enables designs that maximize reliability and operational life.

Bend radius optimization requires balancing flexibility requirements with thermal performance and manufacturing constraints. Smaller bend radii increase mechanical stress but may be necessary for space-constrained applications.

Strain relief design becomes critical in applications involving repeated flexing. Proper strain relief prevents stress concentration at connection points and extends operational life significantly.

Comparison with Alternative Technologies

Flexible Aluminum PCBs vs. Traditional Flexible PCBs

The comparison between flexible aluminum PCBs and traditional flexible PCBs reveals significant performance differences across multiple parameters. Thermal management represents the most significant advantage of aluminum-based designs.

Traditional flexible PCBs, typically based on polyimide substrates, offer excellent flexibility and electrical performance but limited thermal management capabilities. This limitation becomes critical in high-power applications where heat dissipation directly impacts performance and reliability.

| Comparison Factor | Flexible Aluminum PCB | Traditional Flexible PCB |

|---|---|---|

| Thermal Conductivity | 1.5-8.0 W/mK | 0.2-0.4 W/mK |

| Cost | Higher | Lower |

| Flexibility | Good | Excellent |

| Thermal Management | Excellent | Poor |

| Weight | Higher | Lower |

| Durability | Excellent | Good |

Flexible Aluminum PCBs vs. Rigid Aluminum PCBs

Rigid aluminum PCBs offer superior thermal performance compared to flexible variants but lack the mechanical adaptability required for many modern applications. The trade-off between thermal performance and flexibility represents a key design consideration.

Rigid aluminum PCBs typically achieve higher thermal conductivity values due to thicker aluminum substrates and optimized thermal interfaces. However, their inability to conform to curved surfaces or accommodate mechanical movement limits their application scope.

The manufacturing complexity of flexible aluminum PCBs generally exceeds that of rigid variants, resulting in higher costs and longer lead times. However, the mechanical advantages often justify these additional considerations.

Cost-Benefit Analysis

The cost structure of flexible aluminum PCBs reflects their specialized materials and manufacturing processes. While initial costs typically exceed those of traditional flexible PCBs, the total cost of ownership often favors aluminum-based solutions in thermally demanding applications.

System-level cost benefits include reduced cooling requirements, improved reliability, and extended component life. These factors often offset the higher initial PCB costs, particularly in high-volume applications.

Design optimization can significantly impact cost-effectiveness by maximizing thermal performance while minimizing material usage. Strategic design choices enable cost-effective solutions without compromising performance requirements.

Manufacturing Challenges and Solutions

Material Selection and Sourcing

Material selection for flexible aluminum PCBs requires careful evaluation of thermal, electrical, and mechanical properties while considering cost and availability factors. The specialized nature of these materials often presents sourcing challenges that require careful supplier qualification.

Aluminum substrate selection involves evaluating alloy compositions, thermal properties, and mechanical characteristics. High-purity aluminum alloys provide optimal thermal conductivity but may increase costs compared to standard alloys.

Dielectric material selection represents a critical decision point, as these materials directly impact both thermal and electrical performance. Advanced materials offering superior performance often come with higher costs and longer lead times.

Process Control and Quality Assurance

Manufacturing process control for flexible aluminum PCBs requires sophisticated monitoring and control systems to ensure consistent quality. The multi-material construction creates additional complexity compared to traditional PCB manufacturing.

Temperature control during manufacturing becomes critical due to the different thermal expansion coefficients of aluminum, copper, and dielectric materials. Precise temperature profiles prevent delamination and ensure proper adhesion between layers.

Quality assurance protocols must address unique failure modes associated with flexible aluminum PCBs, including delamination, thermal cycling effects, and mechanical fatigue. Comprehensive testing programs ensure reliability across expected operating conditions.

Supply Chain Considerations

The specialized materials and processes required for flexible aluminum PCBs create unique supply chain challenges. Limited supplier bases for key materials can impact availability and pricing, requiring careful supply chain management.

Lead time management becomes critical due to the specialized nature of materials and processes. Planning for extended lead times helps ensure project schedule adherence while allowing for material and process optimization.

Quality certification requirements for aerospace, automotive, and medical applications add complexity to supplier qualification processes. Ensuring suppliers meet required certification standards prevents downstream quality issues.

Future Trends and Technological Developments

Advanced Materials Integration

The future development of flexible aluminum PCBs will likely focus on advanced materials that further enhance thermal performance while maintaining or improving flexibility characteristics. Graphene-enhanced dielectric materials represent one promising development direction.

Nanoparticle-filled dielectric materials offer potential for significantly improved thermal conductivity while maintaining electrical insulation properties. Research into optimized particle compositions and distributions continues to yield performance improvements.

Advanced aluminum alloy development focuses on optimizing thermal conductivity while improving mechanical properties for enhanced flexibility. Specialized alloys designed specifically for flexible PCB applications may emerge as volumes increase.

Manufacturing Process Innovations

Additive manufacturing techniques may revolutionize flexible aluminum PCB production by enabling complex three-dimensional structures and integrated thermal management features. Direct metal printing of aluminum substrates with integrated cooling channels represents one potential development.

Advanced coating and lamination processes continue to evolve, offering improved adhesion, thermal performance, and manufacturing efficiency. Automated processes reduce manufacturing variability while improving cost-effectiveness.

Quality control automation through advanced inspection systems and real-time process monitoring will likely improve manufacturing consistency while reducing costs. Machine learning applications may optimize process parameters for specific applications.

Market Growth and Application Expansion

The market for flexible aluminum PCBs continues to expand driven by increasing thermal management requirements in electronic devices. Electric vehicle adoption, LED lighting growth, and 5G infrastructure development represent key growth drivers.

Emerging applications in renewable energy systems, medical devices, and aerospace electronics create new opportunities for flexible aluminum PCB technology. Each application area presents unique requirements that drive continued technological development.

Cost reduction through manufacturing scale-up and process optimization will likely expand the addressable market by making flexible aluminum PCBs economically viable for additional applications.

Environmental Considerations and Sustainability

Recycling and End-of-Life Management

The aluminum content in flexible aluminum PCBs provides significant recycling advantages compared to traditional PCB materials. Aluminum's high recycling value and established recycling infrastructure support sustainable end-of-life management.

However, the multi-material construction creates challenges for efficient recycling processes. Separation of aluminum, copper, and dielectric materials requires specialized processing techniques to maximize material recovery.

Design for recycling principles can improve end-of-life material recovery by selecting compatible materials and avoiding problematic material combinations. This approach supports circular economy principles while maintaining performance requirements.

Environmental Impact Assessment

The environmental impact of flexible aluminum PCBs spans raw material extraction, manufacturing processes, and end-of-life disposal. Aluminum production requires significant energy input, but recycled aluminum content can reduce environmental impact substantially.

Manufacturing process optimization focuses on reducing waste, energy consumption, and hazardous material usage. Cleaner production techniques and renewable energy utilization further reduce environmental impact.

Life cycle assessment studies help quantify environmental impacts and identify optimization opportunities. These studies support informed decision-making regarding material selection and process optimization.

Regulatory Compliance

Environmental regulations increasingly impact PCB manufacturing, requiring compliance with restrictions on hazardous substances and waste management requirements. RoHS compliance ensures restriction of hazardous materials in electronic products.

REACH regulation compliance requires careful evaluation of chemical substances used in manufacturing processes. This regulation particularly impacts dielectric materials and processing chemicals.

Regional environmental regulations create additional compliance requirements that vary by manufacturing location and target markets. Understanding regulatory landscapes helps ensure compliance while minimizing business disruption.

Quality Standards and Certifications

Industry Standards Compliance

Flexible aluminum PCBs must comply with various industry standards depending on target applications. IPC standards provide comprehensive guidelines for PCB design, manufacturing, and testing procedures.

IPC-4101 specification addresses dielectric materials used in PCB construction, providing guidelines for material selection and qualification. This standard helps ensure consistent material performance across suppliers.

IPC-6013 specification covers flexible PCB requirements, including mechanical, electrical, and environmental performance criteria. Compliance with this standard ensures basic performance requirements are met.

Application-Specific Certifications

Automotive applications require IATF 16949 certification for quality management systems, ensuring consistent quality and reliability in automotive supply chains. This certification addresses automotive-specific requirements and failure mode prevention.

Aerospace applications demand AS9100 certification, addressing quality management requirements for aerospace and defense applications. This certification ensures compliance with stringent reliability and traceability requirements.

Medical device applications require ISO 13485 certification for quality management systems specific to medical devices. This certification addresses biocompatibility, sterilization, and patient safety requirements.

Testing and Validation Protocols

Comprehensive testing protocols ensure flexible aluminum PCBs meet performance requirements across all relevant parameters. These protocols address thermal, electrical, mechanical, and environmental performance characteristics.

Thermal testing includes thermal conductivity measurements, thermal cycling tests, and thermal shock evaluations. These tests verify thermal performance under various operating conditions and ensure reliability over expected temperature ranges.

Electrical testing encompasses standard PCB electrical tests with additional considerations for the effects of flexing on electrical performance. These tests ensure electrical integrity is maintained throughout expected operational conditions.

Mechanical testing evaluates flex life, bend radius limitations, and adhesion strength between layers. These tests predict operational life and identify potential failure modes under mechanical stress.

FAQ Section

What is the main advantage of flexible aluminum PCBs over traditional flexible PCBs?

The primary advantage of flexible aluminum PCBs is their superior thermal management capability. While traditional flexible PCBs typically offer thermal conductivity values of 0.2-0.4 W/mK, flexible aluminum PCBs provide thermal conductivity ranging from 1.5-8.0 W/mK. This represents a 4x to 20x improvement in heat dissipation capability, making them ideal for high-power applications where heat generation is a concern. Additionally, the aluminum substrate provides better mechanical stability and durability while maintaining the flexibility required for curved or space-constrained applications.

What are the typical applications where flexible aluminum PCBs are most beneficial?

Flexible aluminum PCBs excel in applications requiring both thermal management and mechanical flexibility. Key applications include LED lighting systems (especially curved LED strips and automotive lighting), power electronics in electric vehicles, consumer electronics with high-power processors, automotive under-hood electronics, and wearable devices where heat dissipation and comfort are critical. They are particularly valuable in applications where traditional cooling methods are impractical due to space constraints or where the PCB must conform to curved surfaces while managing significant heat loads.

How do flexible aluminum PCBs compare in terms of cost to other PCB technologies?

Flexible aluminum PCBs typically have higher initial costs compared to traditional flexible PCBs due to specialized materials and manufacturing processes. However, the total cost of ownership often favors flexible aluminum PCBs in thermally demanding applications. The superior thermal management reduces or eliminates the need for additional cooling solutions, improves component reliability and lifespan, and can enable more compact designs that reduce overall system costs. The cost-effectiveness improves significantly in high-volume applications where the manufacturing scale helps offset the higher material and process costs.

What are the main design considerations when working with flexible aluminum PCBs?

Key design considerations include optimizing circuit layout for thermal transfer to the aluminum substrate, managing thermal expansion differences between materials, selecting appropriate bend radii to balance flexibility with reliability, and implementing proper strain relief in flex zones. Component placement should prioritize thermal coupling for heat-generating components, while copper trace routing must avoid sharp corners in flex areas. The dielectric material selection significantly impacts both thermal and electrical performance, requiring careful evaluation of application requirements. Additionally, designers must consider the minimum bend radius limitations and expected flex life requirements for their specific application.

What quality standards and certifications apply to flexible aluminum PCBs?

Flexible aluminum PCBs must comply with various industry standards depending on their intended application. General PCB standards include IPC-4101 for dielectric materials and IPC-6013 for flexible PCB requirements. Application-specific certifications include IATF 16949 for automotive applications, AS9100 for aerospace and defense applications, and ISO 13485 for medical device applications. Additionally, environmental compliance standards such as RoHS (Restriction of Hazardous Substances) and REACH regulations apply to materials and manufacturing processes. Quality assurance requires comprehensive testing protocols covering thermal performance, electrical characteristics, mechanical properties, and environmental resistance to ensure reliable operation across expected conditions.

No comments:

Post a Comment